An Essential Manufacturing Partner to the World’s Best Brands

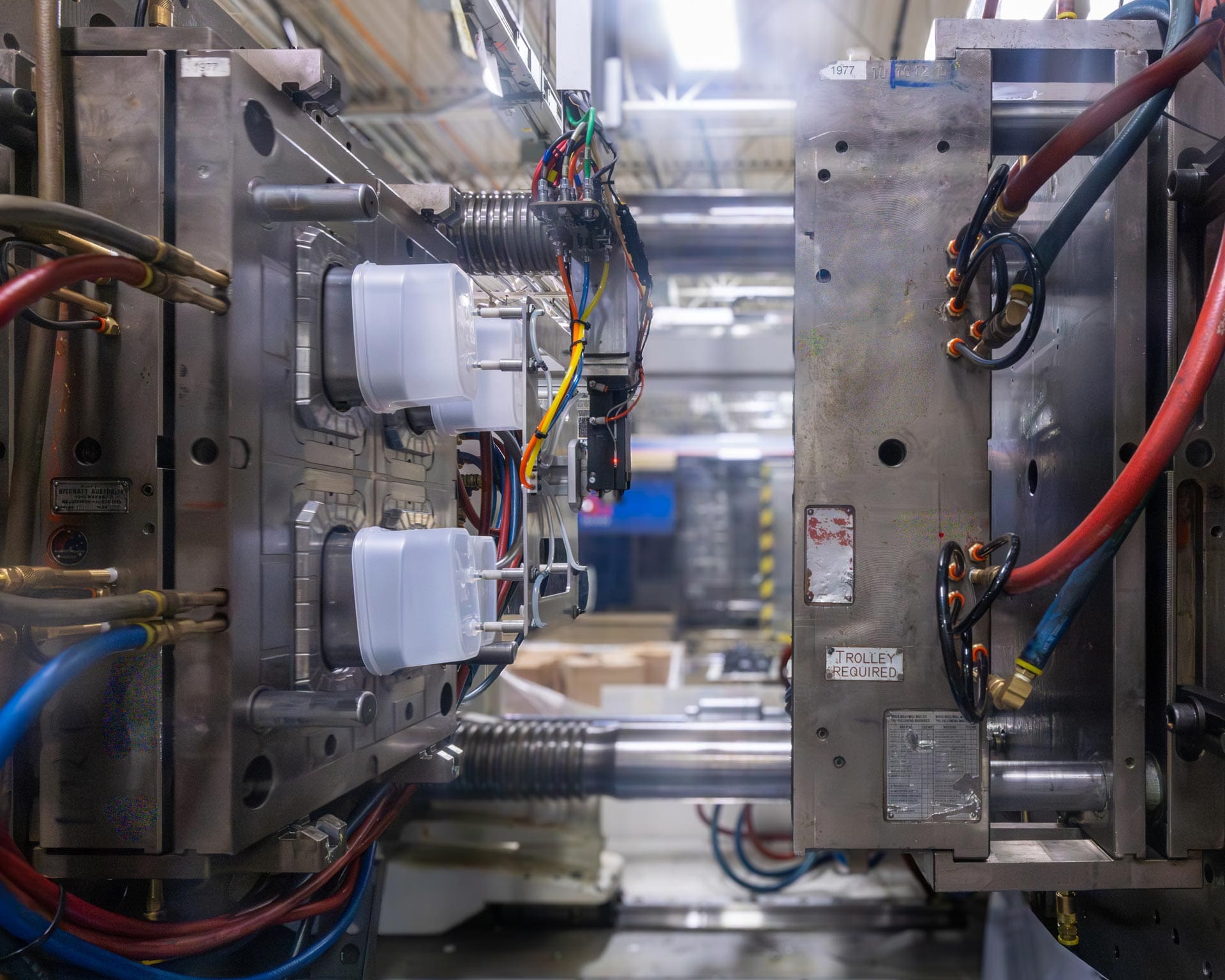

With more than four decades of proven success, Sussex IM is a plastic injection molding company that combines advanced manufacturing, smart automation, and expert collaboration to bring your ideas to life. We offer end-to-end custom injection molding and contract manufacturing solutions – including pad printing, insert molding, and design for manufacturing – from our vertically integrated facilities in Wisconsin.