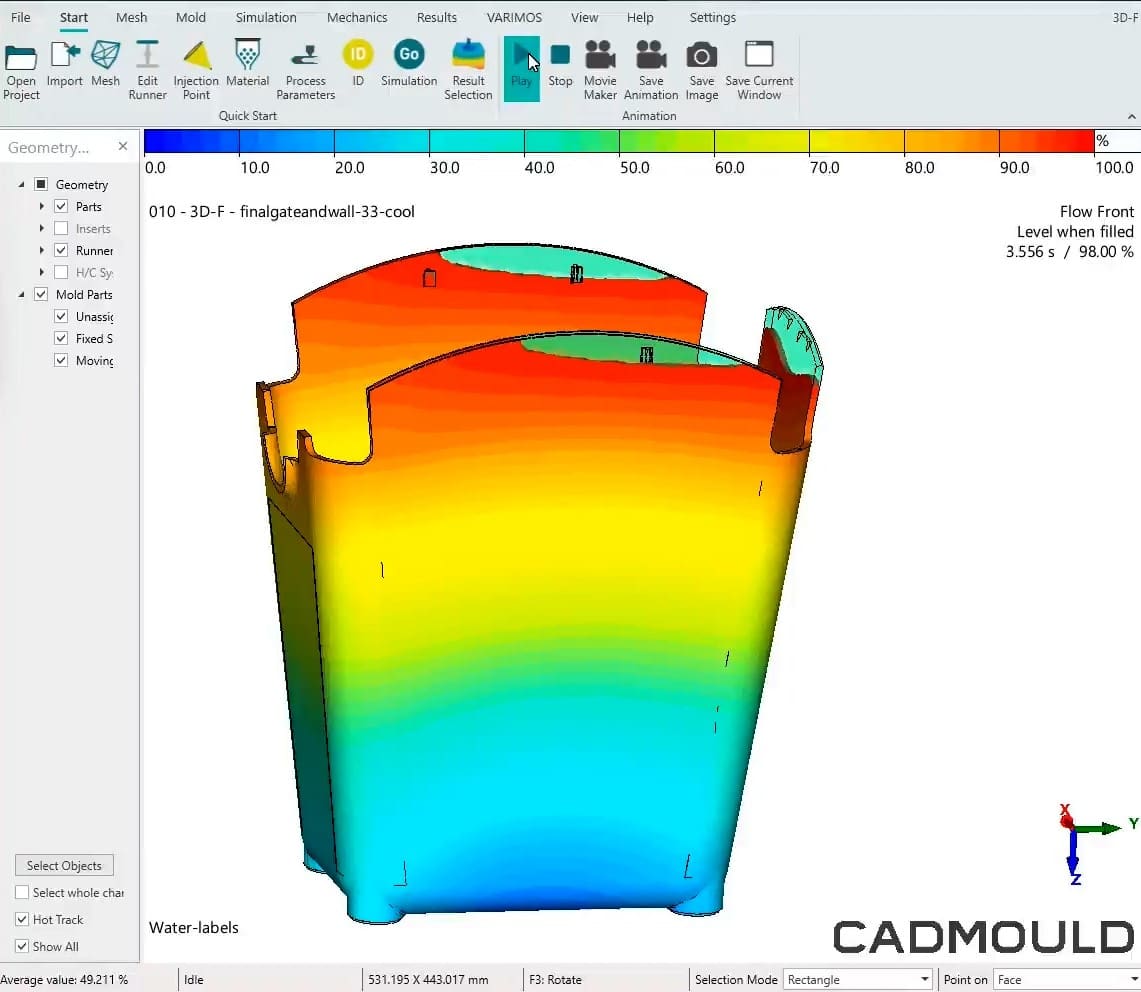

As part of our suite of Design for Manufacturing (DFM) services, we offer molding simulations to help our customers create higher-quality parts at a lower overall cost. Molding simulations are a software-based simulation of the injection molding process that enables engineers and designers to predict potential issues and inefficiencies before a mold is built. Join us as we explore some of the key features, benefits, and applications of molding simulations.

Key Features

Since the molding simulation is performed before the construction of the mold, the simulation can help engineers optimize the mold design. The placement of gates, runners, and cooling channels can be assessed and modified before construction. Teams can also evaluate for uniform material flow, efficient cooling, and reduced cycle times through these simulations. This preemptive testing also enables engineers to analyze various materials and select the best material for the job. Different resins have different flows and characteristics, which have a significant impact on the molding process. Material selection is a crucial step in the production process, and molding simulations can ensure that the correct material is selected for each product and mold.

Benefits

Quicker Timelines: By anticipating issues before production, molding simulations can help accelerate the timeline from design to production by minimizing the physical prototyping and testing necessary before large-scale production.

Higher Quality: The enhanced mold designs produced through the process of molding simulations promote higher quality standards for parts, with issues like warpage, sink marks, and voids already anticipated and solved during the mold and process design.

Design Validation: Molding simulations also help manufacturing companies ensure a part is well designed for manufacturing. Companies can validate that the parts will meet performance and quality specifications and that the product is fit for production.

Applications

Molding simulations can be used on a variety of products across industries, and the process can be tailored to best fit each product. In the medical industry, simulations can ensure medical devices are manufactured to the highest quality standards, while in the packaging industry, they can optimize production of durable and efficient packaging. Simulations can also be utilized in products with In-Mold Labeling (IML) to optimize label location and adhesion.

Molding simulations are an invaluable tool for designing molds that efficiently produce high-quality products. If you’re ready to learn how we can utilize molding simulations as part of our DFM for your specific needs, contact us today!