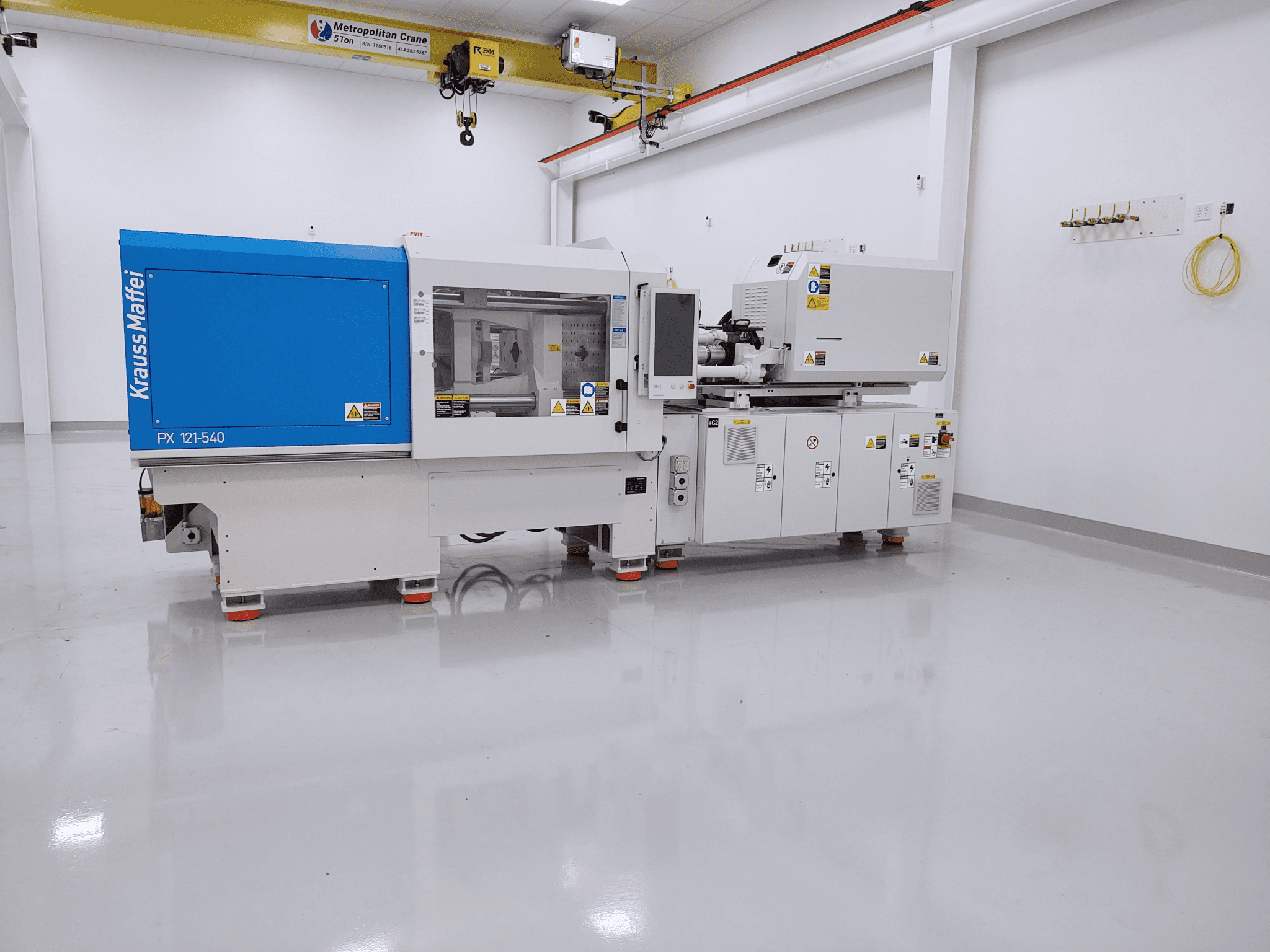

Custom Injection Molding for Medical Devices & Pharma Products

Sussex IM supports the medical and pharmaceutical markets with precision, consistency, and full traceability. Our vertically integrated services include custom medical injection molding and validated manufacturing processes that meet the strict demands of regulated healthcare environments.