Getting a high-quality molded part out of the tool is just as important as getting the material into it. The wrong ejection method can leave scuffs, warp the part, or slow down production. The right one? It keeps things moving smoothly, maintains cosmetic integrity, and ensures efficiency.

Sussex IM doesn’t leave ejection to chance. With over 60 injection molding machines running at our Wisconsin facility, we take a strategic approach to selecting the best method for every project. Whether it’s a high-volume production run, a clear polycarbonate component that can’t afford scratches or a complex part with undercuts, we apply the right tools – ejector pins, air poppets, stripper plates, or automation – to get the job done.

The Ejection Methods That Keep Production Moving

Ejection isn’t a one-size-fits-all process. Different part designs, materials, and manufacturing goals call for different methods. Here’s a closer look at the most effective techniques we use:

Ejector Pins: The Workhorse of Ejection

Ejector pins are one of the most widely used methods in injection molding. They push the part out of the mold cavity after cooling, offering a simple and reliable solution.

Best for: Standard parts with straightforward geometries.

Watch out for: Small marks on the part’s surface, which can be a concern for high-visibility components.

When cosmetic quality matters, Sussex IM carefully places ejector pins in non-critical areas to keep visible surfaces pristine.

Air Poppets: The Gentle Touch

For parts that demand a flawless surface, ejector pins aren’t always the best option. Air poppets use compressed air to release the part from the mold, preventing drag marks or indentations.

Best for: Clear polycarbonate parts or anything requiring a high-end finish.

Watch out for: Not as effective for rigid, high-strength materials that require more force to eject.

Sussex IM turns to air poppets when working with delicate or transparent materials, where even the smallest imperfection can stand out.

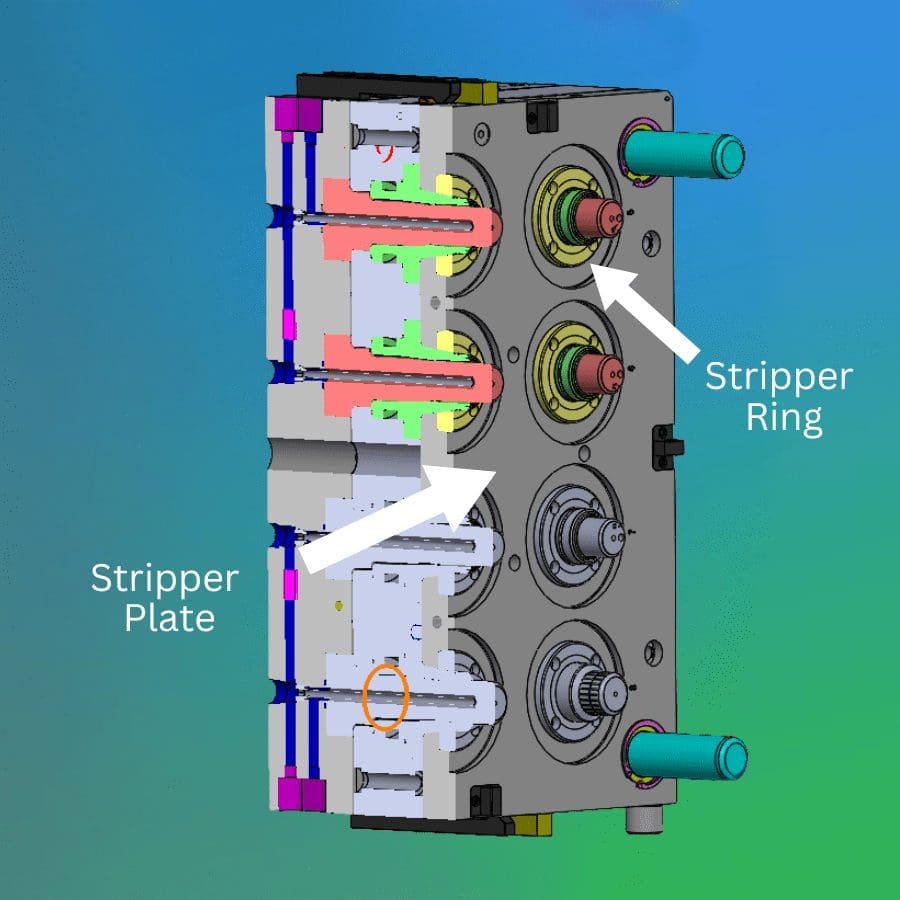

Stripper Plates: Smooth & Even Ejection

Unlike ejector pins, which apply force at specific points, stripper plates distribute pressure across a larger surface area. This reduces stress on the part, making it a great choice for complex shapes or high-volume runs.

Best for: High-production runs with intricate geometries.

Watch out for: A more complex and costly mold setup.

When production demands consistency and efficiency, stripper plates provide the controlled ejection needed to keep operations running smoothly.

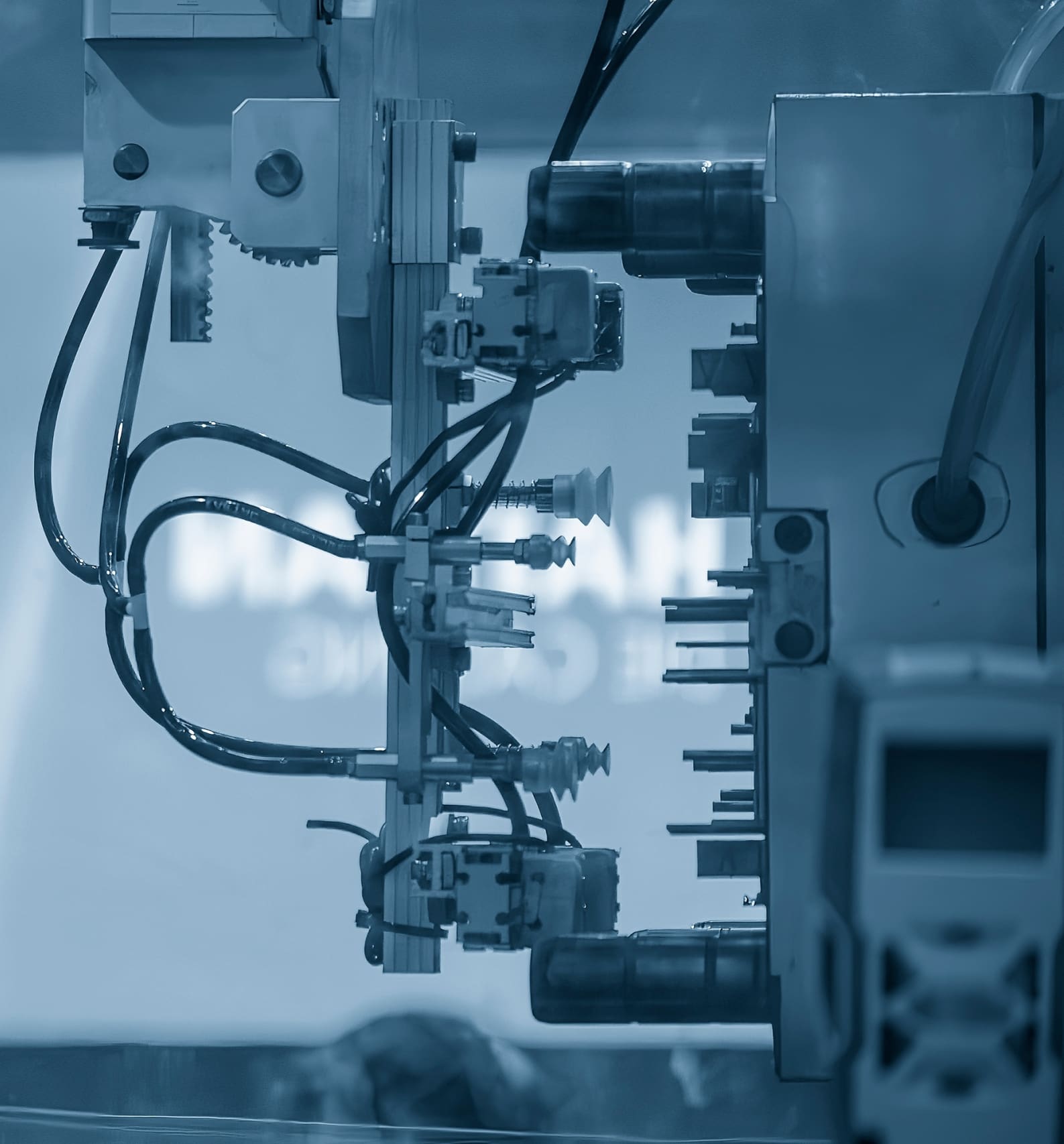

Robot Pick (EOA): Automation for Precision

Automation plays a huge role in modern injection molding, and ejection is no exception. Robotic end-of-arm tooling (EOA) can remove parts from the mold with precision, eliminating the need for mechanical ejection altogether.

Best for: Parts with snap features, undercuts, or thin walls.

Watch out for: Initial investment in setup, though long-term benefits include reduced defects and higher efficiency.

Sussex IM’s in-house automation team customizes EOA solutions for specific projects, walking parts off the mold instead of forcing them out, which prevents damage and improves cycle times.

How Sussex IM Chooses the Right Ejection Method

No two projects are alike, and choosing the right ejection method depends on a variety of factors, including:

- Cosmetic Requirements: High-visibility parts require methods that won’t leave blemishes. Air poppets and robotic handling often come into play here.

- Part Complexity & Geometry: Snap features, deep draws, or undercuts might require lifters, customized ejector bars, or stripper plates.

- Material Properties: Glass-filled nylon needs more force to eject, while soft plastics like polycarbonate demand gentler methods.

- Production Volume: Stripper plates shine in high-volume production, offering consistent ejection across thousands of cycles.

- Automation Needs: For precision and efficiency, Sussex IM incorporates robotic handling and in-house automation strategies.

Each of these elements gets considered long before production starts. Our engineers, toolmakers, and automation specialists work together from the start, anticipating potential ejection challenges so that everything runs smoothly when the mold goes into production.

Common Ejection Challenges & How Sussex IM Solves Them

Even with the right method, ejection can present challenges. Here’s what can go wrong – and how we get ahead of it:

- Warping or Deformation: Parts can bend or warp if ejection force isn’t distributed evenly. Sussex IM optimizes mold cooling and ejection techniques to reduce stress and keep parts true to form.

- Sticking to the Mold: Sometimes, parts don’t want to release easily. Adding undercuts or modifying mold coatings improves release and prevents slowdowns.

- Surface Defects: Drag marks, dents, or other blemishes can result from improper ejection. Air poppets, automation, and precise mold finishes keep cosmetic quality intact.

These issues don’t come as surprises at Sussex IM. Engineers and automation specialists evaluate potential problems early in the process, making adjustments before the mold is even set in the press.

Advancing Ejection Techniques for Better Performance

Every project presents its own set of challenges, and Sussex IM continues refining its ejection methods to improve part quality and manufacturing efficiency. Some of the strategies that set us apart include:

- Customized End-of-Arm Tooling (EOA): Reduces manual handling and improves precision.

- Stripper Plate Integration: Supports high-volume production runs by preventing uneven ejection forces.

- Air Poppet Optimization: Reduces cosmetic defects in clear and high-visibility parts.

- Strategic Mold Design: Balances material behavior with ejection force to prevent sticking or warping.

Having in-house automation, tooling, and engineering teams means we can adapt ejection methods for each customer’s specific needs. Instead of relying on a single approach, we use the right combination of techniques to maximize efficiency and minimize defects.

Final Thoughts

The ejection process is more than just getting the part out of the mold – it’s about getting it out right. Sussex IM applies decades of expertise to tailor ejection methods for every project, ensuring smooth production, cosmetic quality, and efficiency.

Whether it’s ejector pins for simple designs, air poppets for premium finishes, or fully automated handling for delicate geometries, our team works upfront to get the details right. A well-planned ejection strategy improves part quality, saves time, reduces waste, and keeps manufacturing moving.

Need an injection molding partner who understands every detail of production? Contact us today to get started!