Injection Molding Services That Deliver Consistency, Speed, and Scale

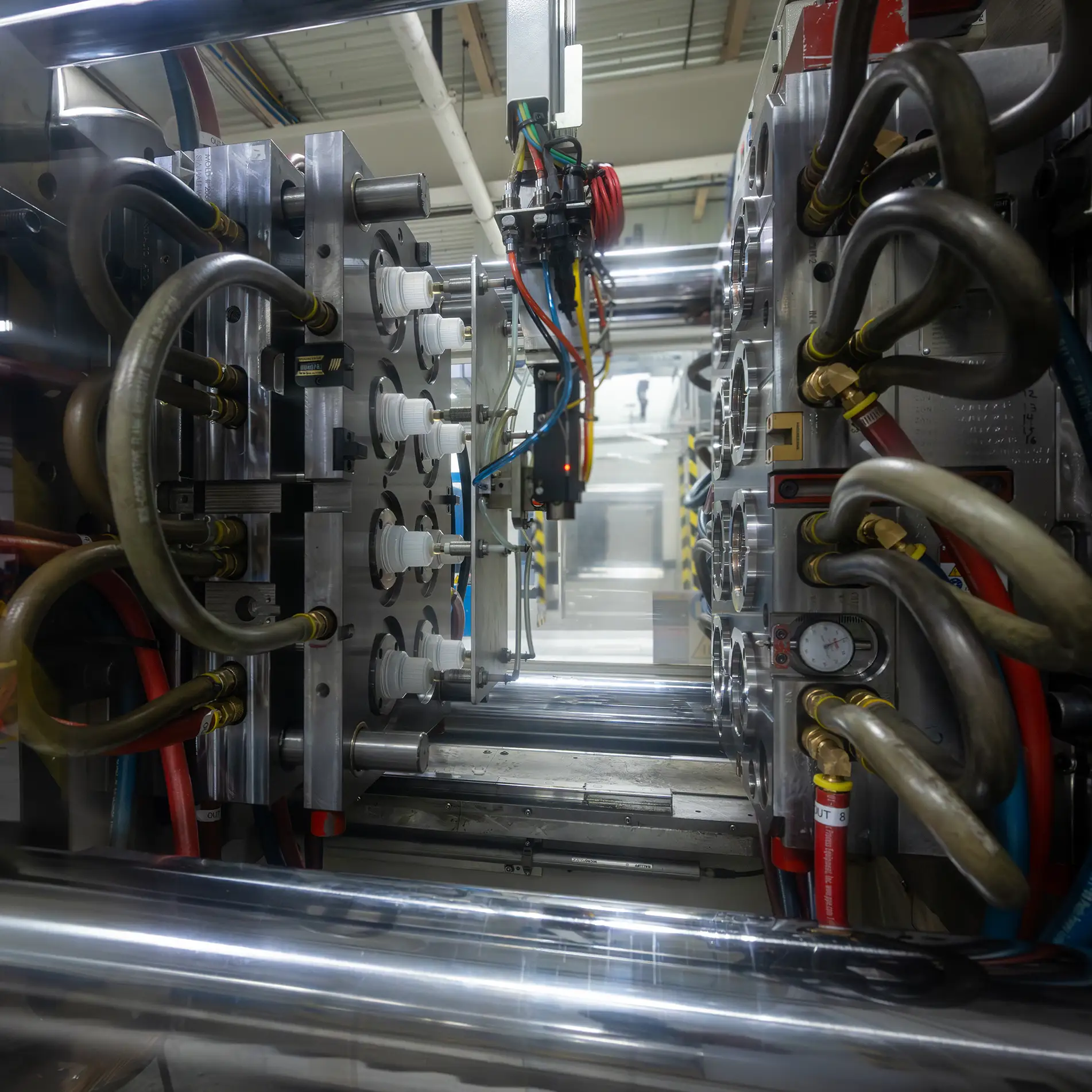

Injection molding is at the heart of what we do at Sussex IM. With more than 65 molding machines and decades of hands-on experience, we support high-volume production with the precision and repeatability our customers count on.

As a full-service plastic injection molding manufacturer, we manage every stage in-house, from design for manufacturing and transfer tooling to automation, assembly, and delivery. That means tighter control, faster response times, and seamless execution across the board.

Our presses range from 25 to 725 tons, giving us the flexibility to mold everything from small medical components to large industrial housings. Sussex IM is equipped to handle new product launches, reshored programs, and complex production needs—efficiently, reliably, and at scale.