What is a Gate?

In the injection molding process, the gate is the entry point through which molten plastic fills the part. It is the transition from the mold’s runner system into the part cavity and separates the runner from the finished plastic component.

The size, shape, and placement of the gate are critical to part quality, cycle time, and overall molding efficiency. Several different gate types may be selected during the Design for Manufacturing (DFM) process depending on part geometry and end use.

Gate Removal

During cooling, excess plastic solidifies in the gate, creating a tab of material that must be removed in a process called degating. The method of removal—and resulting residue—directly influences many design decisions during DFM.

Automatic vs. Manual Degating

Degating may occur automatically through mold features or manually by an operator after part ejection. The gate style determines which method is required.

Gate Types

Manual Trim Gates

Edge Gate

Placed on the edge or parting line of the mold. Common for square or rectangular parts with thicker walls and multicavity tooling.

Tab Gate

Used for flat or thin parts. Includes an added tab of plastic to support clean trimming.

Sprue Gate

Used for single-cavity molds, where the sprue feeds material directly into the cavity. Common for cylindrical parts.

Automatic Trim Gates

Valve Gate

Instantly cuts off plastic flow, leaving a nearly invisible gate mark. Ideal when gating onto a visible area where cosmetic performance is critical.

Hot Tip

Requires a hot runner system with a heated nozzle to keep plastic molten. Enables faster cycle times and reduces waste. Best for round or conical parts and high-cavitation tooling.

Pin Gate

Used with cold runner systems and employs plates to perform the degating function, offering similar placement flexibility to a hot tip.

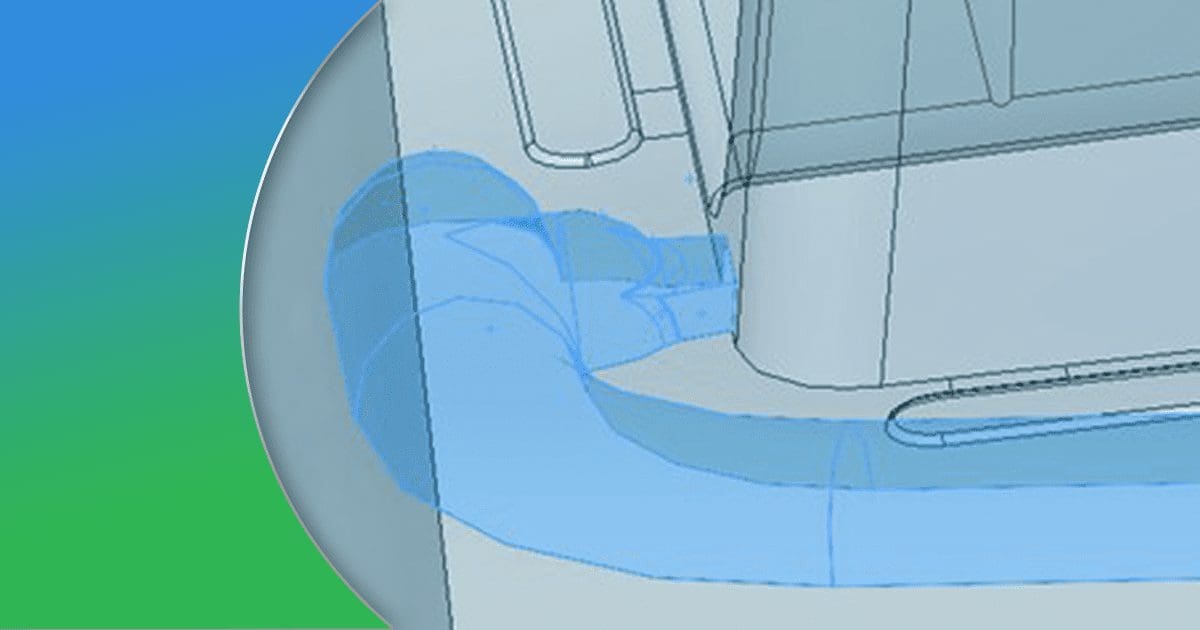

Sub Gate

Fills the part from beneath the parting line through a tapered channel. Useful when hiding gate blemishes is important.

Hot Edge Gate

A hot-tip style gate that simulates a cold-runner sub gate, feeding material into the side of the part with clean separation.

Factors for Deciding Gate Type and Placement

When selecting a gate style and location, designers must evaluate mold flow, pressure, part geometry, resin selection, and end-use requirements.

Additional Factors to Consider:

-

Flow distance, which impacts the number of gates required

-

Cosmetic expectations

-

Gate location to ensure even pack-out

-

Wall thickness, targeting the thickest area for optimal flow and consistent cooling

How Gate Type and Location Affect Part Quality

Gate Type

-

Determines the visual vestige or residue on the part surface

-

Can influence environmental footprint through reduced waste

-

May affect cycle time and overall cost

-

Cleaner gating or reduced runner waste may increase mold cost

-

Higher capital expense can be justified through long-term production savings

-

Opening size limits may influence molding parameters

Gate Location

-

Cosmetic visibility must be considered, as some residue will always remain

-

Placement impacts fill balance and the ability to pack out the part properly

-

Filling thicker sections first reduces sink marks and warpage

-

Flow direction affects shrinkage and overall dimensional stability

The Sussex IM Difference

Gate style and placement involve a complex decision-making process that Sussex IM evaluates at the time of quotation. By considering cost, speed to market, quality, aesthetics, and functional requirements, Sussex ensures your part design is optimized for molding efficiency and final performance. These choices ultimately influence both mold cost and part cost.

To support the DFM process, Sussex IM provides access to experienced tooling engineers, project engineers, and tool & die makers who analyze each part from molding through final production to recommend the best molding strategy.

To speak with a Sussex IM engineer and learn more about injection-molded part design.