Multi-Shot Molding Services for Complex, Multi-Material Parts

Sussex IM provides advanced multi-shot injection molding solutions that combine multiple materials or colors into a single, fully bonded part – without secondary assembly. From soft-touch grips to multi-color components, we help OEMs create higher-value products with greater efficiency.

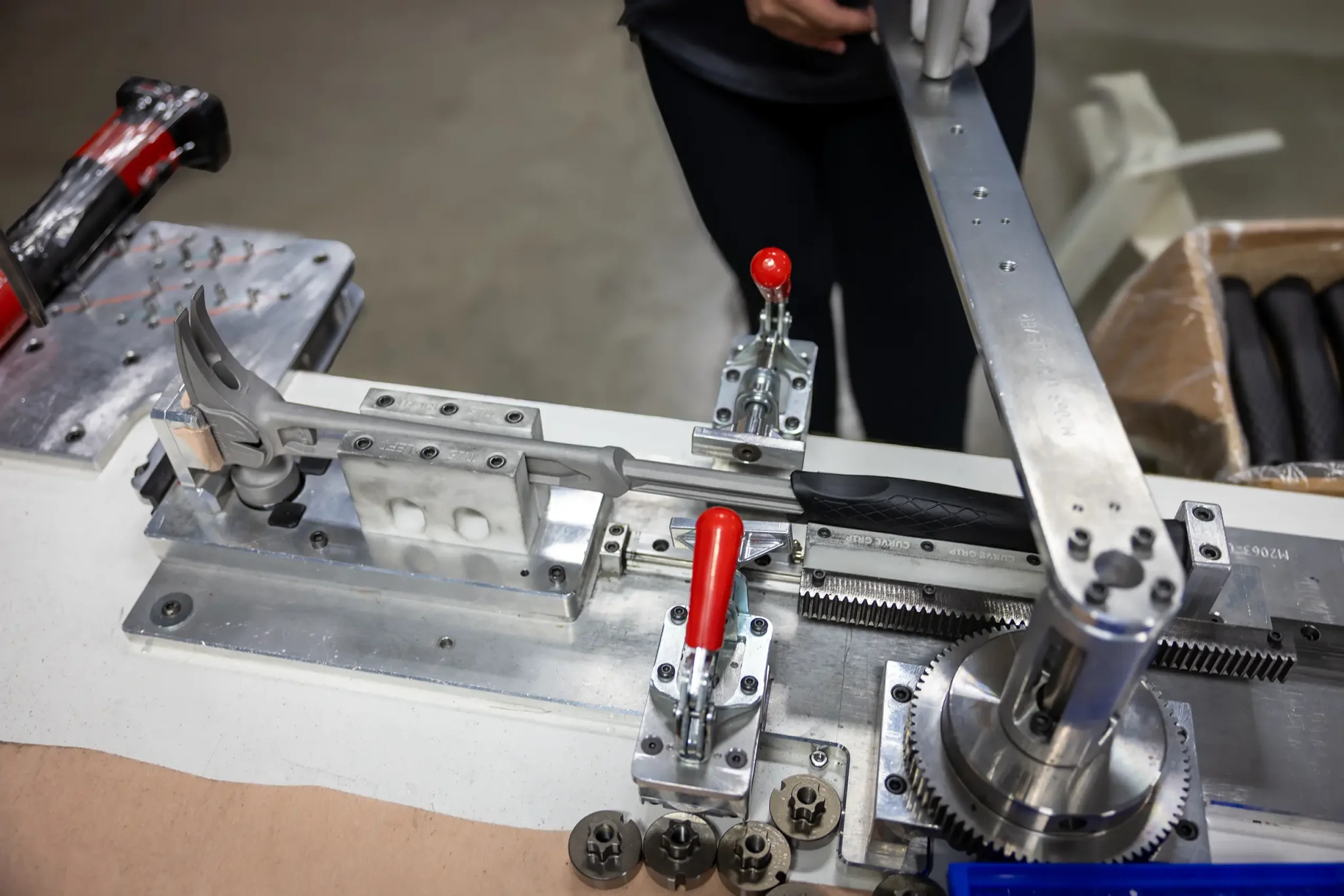

Our team brings decades of experience designing, building, and running custom two-shot injection molding and multi-shot molding work cells. Projects that require dual durometers, clear lenses, embedded electronics, or color contrast benefit from our ability to deliver consistent, repeatable results using a single mold setup.