Plastic Part Decoration That Adds Value and Visual Appeal

At Sussex IM, decoration isn’t an afterthought – it’s part of how we help products stand out. With decades of experience serving cosmetics and consumer brands, we offer a full range of plastic part decoration services tailored to material, performance, and aesthetic goals.

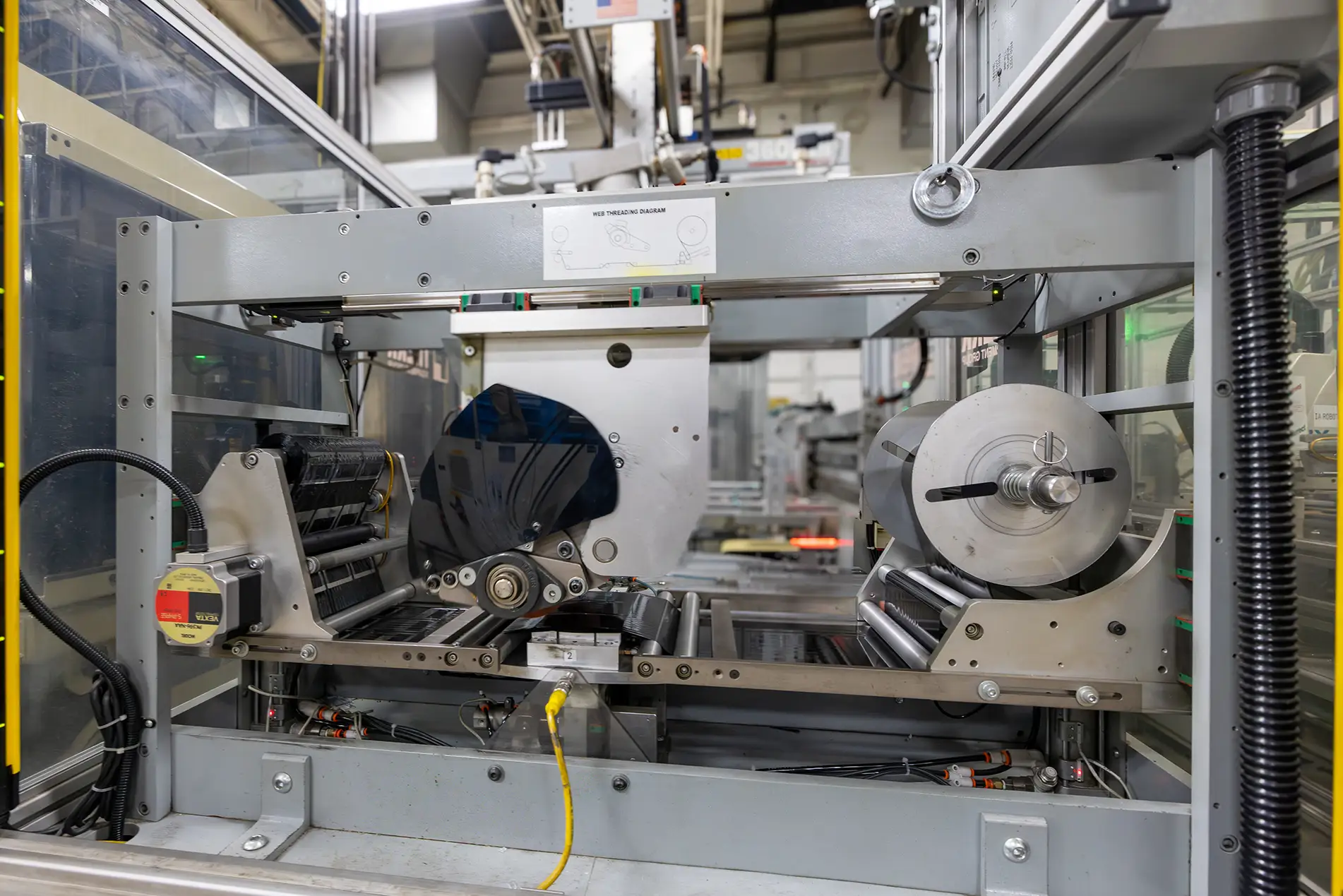

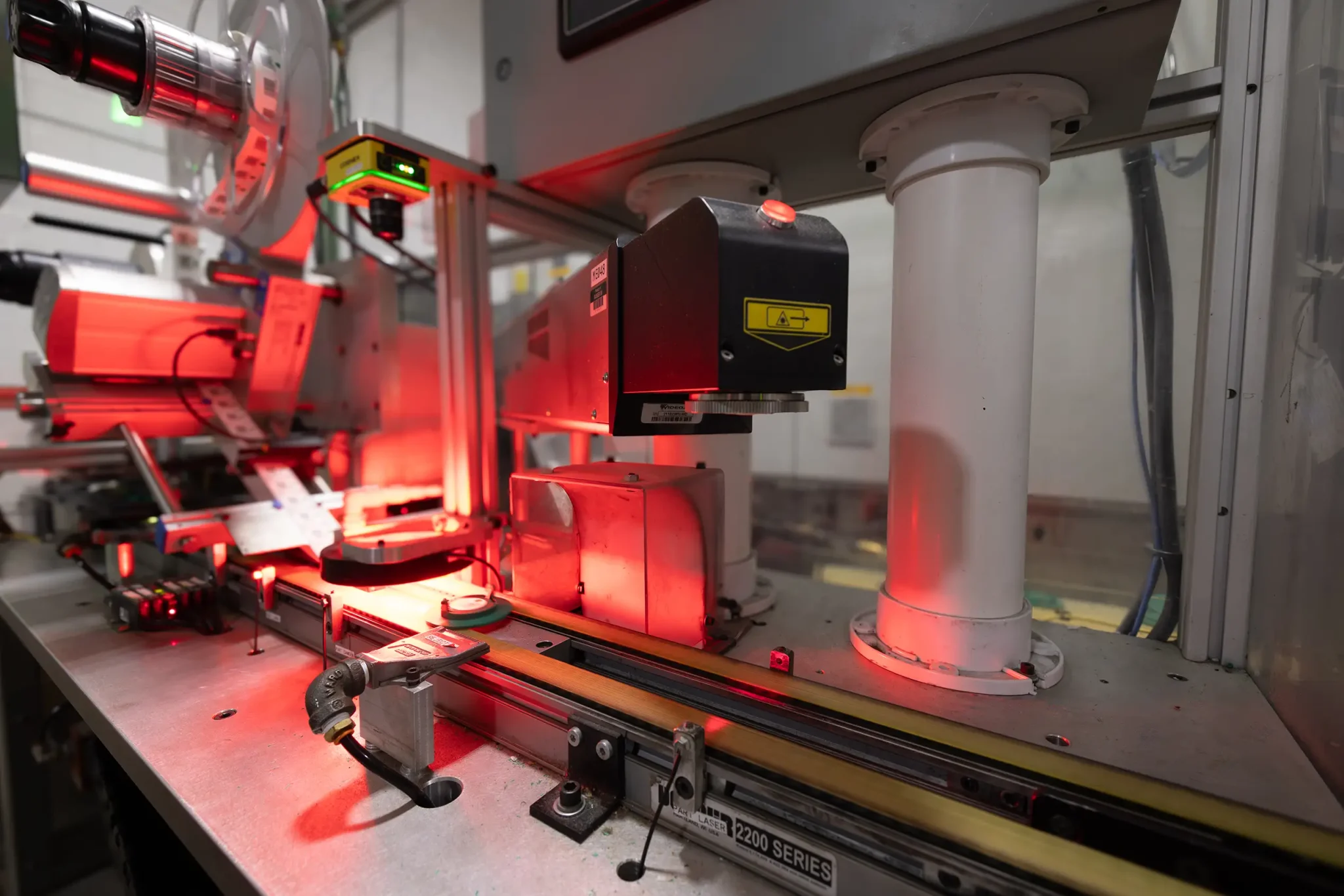

From simple branding to complex multi-color graphics, our in-house capabilities cover pad printing, hot stamping, heat transfer, and in-mold labeling (IML). Every technique is evaluated for durability, visual clarity, and compatibility with your molded part and substrate.