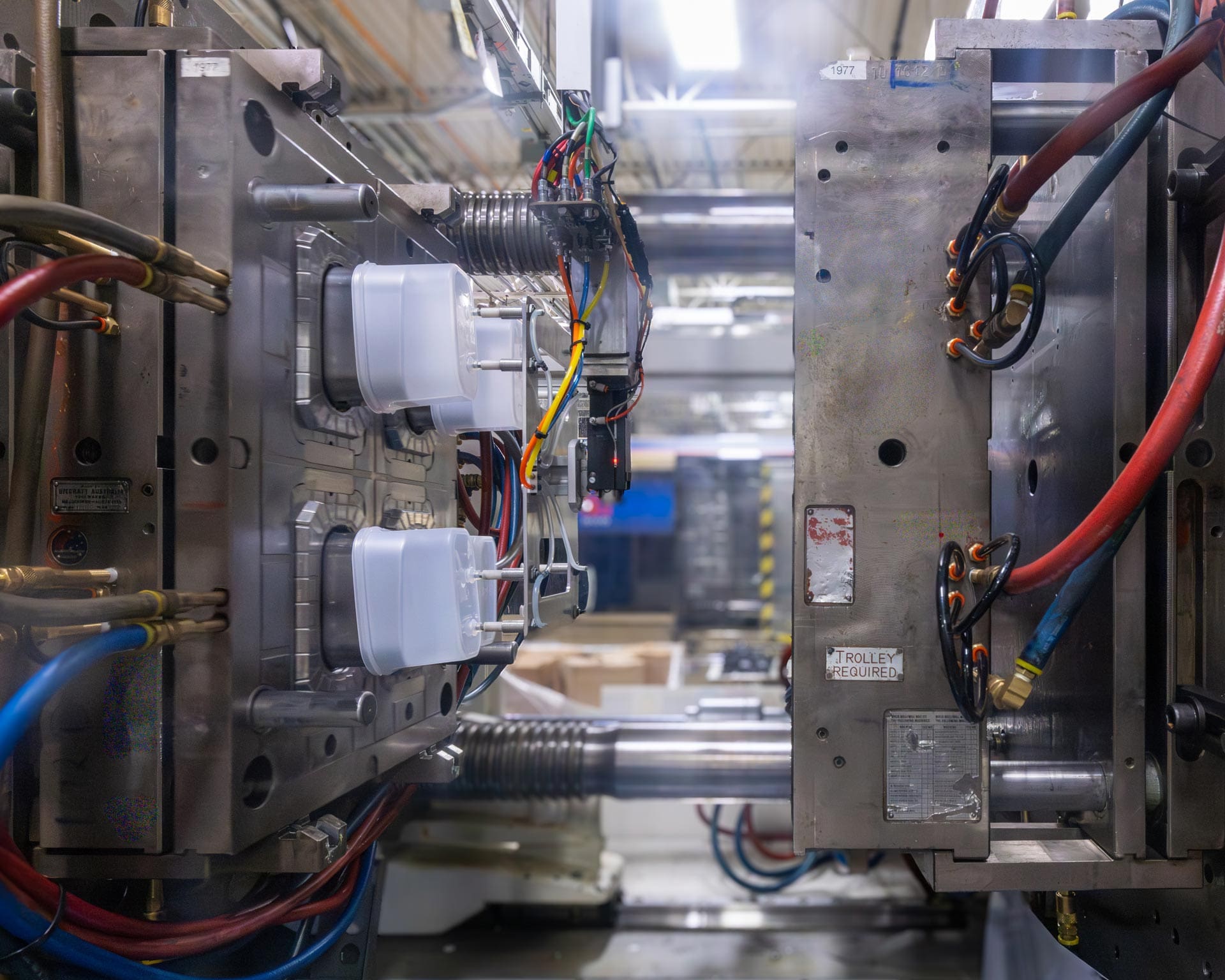

Injection Molding Solutions for Food Service Products

Sussex IM supports food service brands with reliable, hygienic, and high-performance plastic parts. Our custom injection molding services meet the standards required for food contact applications, handling equipment, and sanitation systems – delivered with attention to consistency, cleanliness, and compliance.

We understand the unique requirements of this industry and provide technical support to help customers select materials, optimize part design, and scale production efficiently.