Copyright 2026 | All Rights Reserved | Sussex IM | Privacy Policy | Terms & Conditions

Powered by Vive Marketing

Sussex IM Timeline

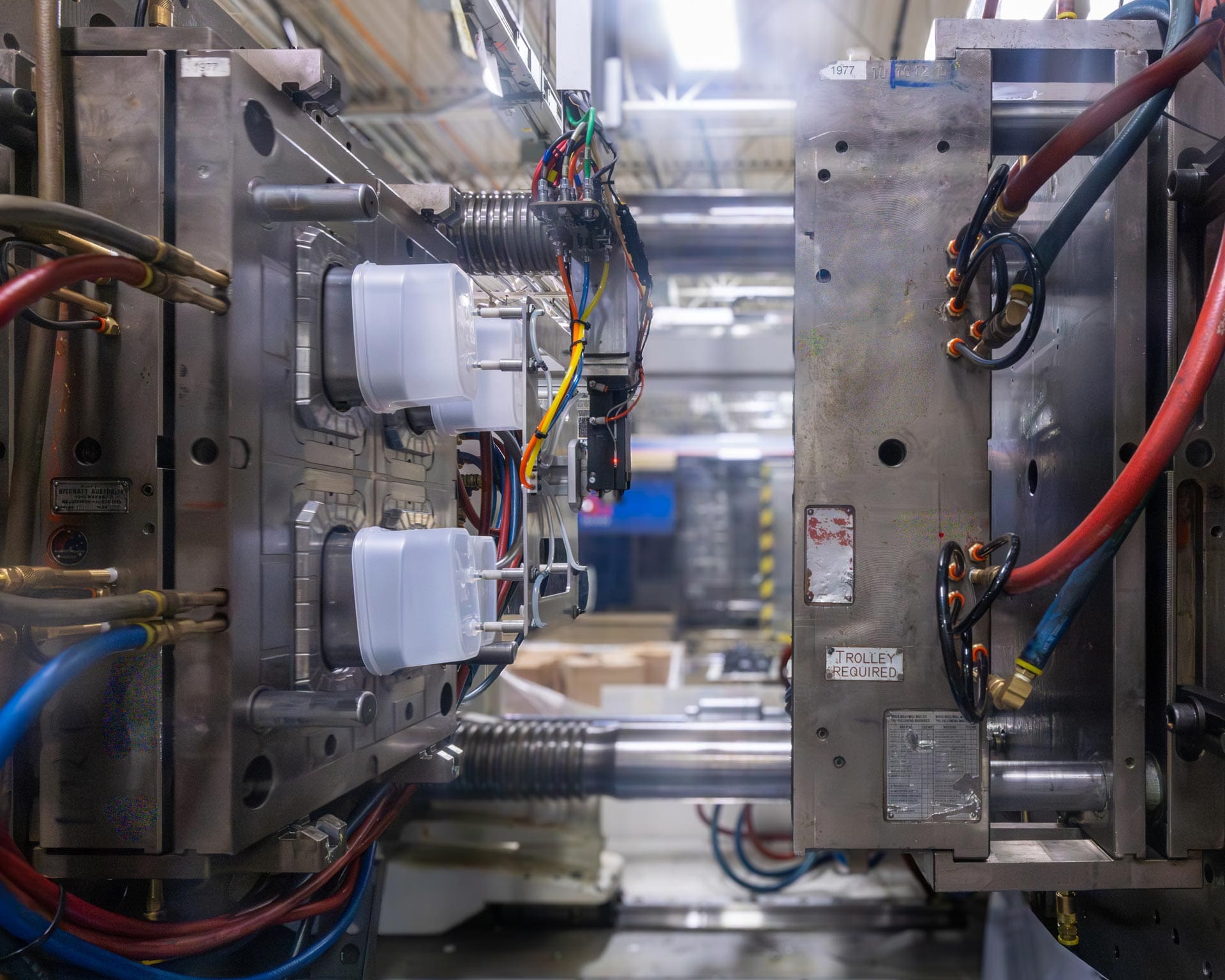

1977: The Beginning

Our story begins with Lorand Spyers-Duran, an ambitious Hungarian immigrant who came to the U.S. in 1956. After settling in Sussex, Wisconsin and gaining experience at Hartland Plastics, Lorand followed his entrepreneurial instincts and co-founded Sussex Plastics, Inc. with three partners.

The team secured used equipment at auction, set up shop, and got to work. One of the company’s first orders came from Liquid Metronics (LMI) for metering pump components.

1980s: Blow Molding Takes Off

Sussex Plastics expanded its expertise into blow molding, a process distinctly different from injection molding. The company’s first blow molded product? Candy cane handles – millions of them, produced year-round.

To support growing demand, the facility expanded by 40,000 square feet with added space for offices, warehousing, and manufacturing. In 1987, Avon named Sussex Plastics its Supplier of the Year, a notable recognition for a 10-year-old company with a reputation for quality and dependability.

1990s: Bigger and Better

Growth continued into the 1990s with another 45,000-square-foot expansion, complete with new resin silos to support production.

By the end of the decade, Sussex Plastics was acquired by Rexam, a $6 billion global packaging leader. This era brought new opportunities and positioned the company to serve larger, more complex markets as an international injection molding manufacturer.

2000s: Innovation to Grow

As markets grew more competitive, Sussex adapted. The company anticipated its customers’ need to stay ahead through product differentiation, investing in a 10,000-square-foot Innovation Center and the advanced Motan material handling system.

The facility was also upgraded with air conditioning to improve comfort and productivity – a testament to Sussex’s employee-focused culture. These advancements helped lay the foundation for Sussex’s position as a custom injection molding leader with full in-house capabilities.

2010s: Becoming Sussex IM

Following the 2008–2009 recession, Rexam began consolidating its operations. Rather than see the Sussex plant close, three members of the management team – Phil Salzman, Keith Everson, and Dave Guagliardo – stepped in to purchase the business. Sussex IM was born, preserving approximately 220 jobs and bringing the company back to its core values.

What followed was a run of sustained, double-digit growth. A 12,000-square-foot expansion was completed, and Sussex IM South – now our Advanced Manufacturing Facility – was developed with 86,000 square feet dedicated to streamlined, pellet-to-pallet operations. This period marked Sussex’s transformation into a vertically integrated injection molding company.

2020s: New Look, New Opportunities

The COVID-19 pandemic accelerated demand in the Health & Hygiene sector. Sussex IM responded with agility, expanding into the medical market to support medical device injection molding.

This growth was accompanied by a full rebrand, reflecting the company’s vibrant culture and advanced technology. An additional 71,000 square feet was added to the Advanced Manufacturing Facility, including climate-controlled warehousing to support continued expansion.

In 2019, Sussex IM was named Supplier Innovator of the Year by Gojo Industries, just one of many recognitions that highlight our role as a trusted custom injection molder and problem-solving partner.

2024: A New Chapter Begins

Sussex IM entered a new era of leadership in 2024, transitioning from first-generation ownership to the second generation. While the name and values remain the same, this next chapter brings renewed energy and continued commitment to our customers, our team, and the future of U.S. manufacturing.