Test Early. Refine Quickly. Move Forward with Confidence.

Plastic prototype manufacturing offers a critical advantage during product development. Holding a physical part rather than relying solely on CAD gives teams the ability to assess fit, function, and manufacturability before committing to full-scale production. Adjustments at this stage save time, reduce cost, and help prevent design issues from reaching the manufacturing floor.

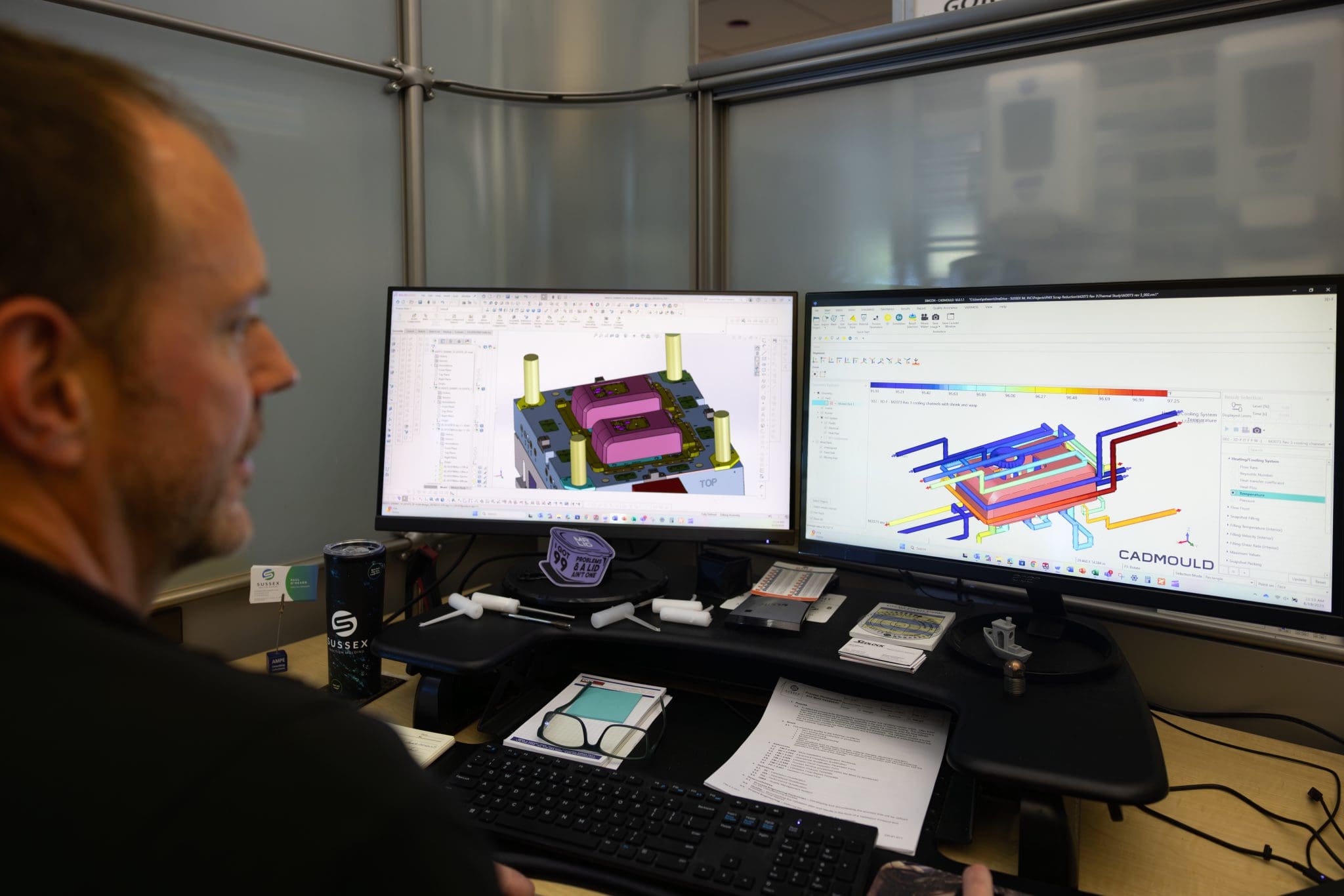

At Sussex IM, plastic prototyping support is more than a one-size-fits-all service. Our engineers evaluate your goals and timeline to recommend the best approach, whether that involves a quick-turn 3D printed sample or an aluminum mold for short runs.